What you need to know about molding?

Molding is a wonderful tool, which allows to create and implement amazing architectural ideas. Thanks to it, all objects gain both the value and the appearance. Despite the fact that moldings are not an invention, there is still a room for innovation in this branch. Relying on the opinions of thousands of our customers, we can state that our products significantly stand out from competitors.

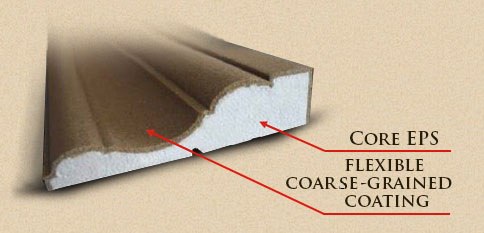

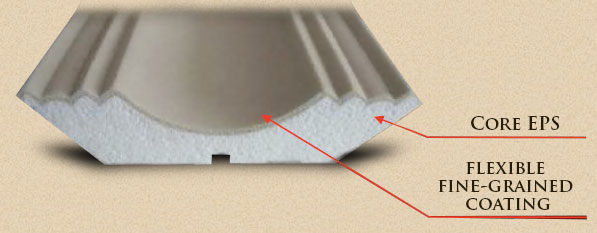

Our interior and exterior moldings are made of composite material, which gives them exceptional properties. The core is made of expanded or extruded polystyrene, which makes profiles light and inexpensive. On the other hand, the polystyrene core is covered by our special polymeric stucco. This feature not only gives strengths and flexibility, but also increases durability of profiles and makes them totally insensitive to any external factors, such as hailstorms, temperature range extremes, UV rays, moisture and insects.

Molding Creator has been rewarded for its products at many building exhibitions. All products are certified to be used in construction, both private and public buildings.

Facade profiles

The core of our profiles is made of the high-quality expanded polystyrene EPS-200 or extruded XPS-30, the surface is covered with the coarse-grained elastic polymeric coating. Our profiles do not have any reinforcement mesh, what makes them easy-to-mill. The profiles are supplied in sections of 120 cm or 225 cm. The average thickness of protective layer is 2-4 mm. However, it’s enough to withstand extreme weather conditions like hailstorms. Moreover, water absorbability of the profiles do not exceed 1%

Interior Profiles

Our moldings are produced in sections of 120 cm and 225 cm for EPS core and 125 cm for XPS. The profiles are cut perfectly and lack the effect of fraying edges. The exceptional elasticity of the profiles enables fitting them to uneven walls without any difficulties. Some of the profiles can be bent into an arch.

WHY CHOOSE US?

Our building materials are fully compatible.

Our customers may fully embody their ideas both during construction, design and renovation of their house. All produced materials were designed in such a way that they can be easily combined and never exclude each other. On the choice of a customer, we offer more than 300 different molding designs. Moreover, we can supply our clients with totally customized profiles. All produced materials were designed in such a way that they could easily work together and would not exclude each other.

From information we have received from our customers, we know that other companies sometimes produce decoration systems, where some parts do not work with each other. This fact results in joint cracks, cracks on bonding, profiles’ unsticking and paint’s flaking.

We have designed a protective cover which withstand extreme weather conditions.

Below we present two pictures of the Molding Creator molding coating after 4 years in extreme weather conditions: rainfalls directly onto the moulding and the temperature difference of 120ºC (248ºF).

We have tested a lot of exterior profiles which are produced in different European countries. None of those products sustained the conditions we test our moldings in. Below You can observe products from other manufacturers and the effects caused by weather.

A protective layer is crumbled, cracked and prised from the polystyrene core. The brittleness of the material was caused by UV. The extreme result was a total falling off of the cover from the polystyrene core.

Our profiles can be transported to every place in the world without any risk of damage.

Due to the exceptional properties of our cover we can transport it everywhere without any damage. ‘The competitive’ products have some problems with transport because they are usually delivered damaged to some extent (dents and cracks – information from individual customers, warehouses and contractors).

Our exterior mouldings are hail-resistant.

Thanks to the proper thickness, flexibility and endurance our protecting cover is hail-resistant. Clients often call us to ask what they should do with moldings they had bought from competitive companies and which have been damaged during a hailstorm. The reason for a damage is a very brittle and thin protecting layer (companies savings).

In ‘competitive’ companies we can also observe a loss of flexibility after some time. In this situation every hailstorm causes some additional damage of a molding.

Our exterior moldings has a very low water absorption.

Our high-quality materials make the protective cover very low water-absorbing: it is only 1% of water absorbability. This is an absolute record we have achieved. Different types of moldings available on the market have even several dozens percent of water absorption. This fact compel householders to renovate facades soon.

Our covered moldings do not lose any flexibility after some time.

After four years our covered profiles did not loose any flexibility.

They can be stored easily and installed in convenient time. The other products we have tested demonstrated significant loss of flexibility after some time. So, cracks and breaks occur frequently during installation.

You get a very detailed installation instruction.

Each our client gets an illustrated step-by-step installation instruction. All those who use our materials and work according to its recommendations enjoy quality and endurance.